Our Capabilities

SMT Manufacturing & Supply, LLC produces machined parts and assemblies to our customer's specifications with high precision tolerances and automotive cosmetics. Success in the field of precision machining requires a certain uniqueness. Our commitment to total customer service is "system oriented", emphasizing a long-term relationship wherein open communications result in continuous improvements in engineering, manufacturing processes, quality conformance, and bottom line costing. Our customer becomes part of our team right from the start of the quote, working directly with our engineering, processing, tooling and quality staff to clearly establish requirements and optimal procedures. We emphasize prevention of problems, not repair.

We work with our customers to create a true partnership and look at total cost and benefits such as shortened lead times by working with us as their "complete" supplier. Our approach to the manufacturing process is to create a flow-through structure, starting with the arrangement of a "cell", so all operations carried out on the part are completed in one handling, with no queuing or transfer to another piece of equipment. In many cases we can also perform additional processes such as pressing bearings as part of the cell function. We also continually acquire technologically advanced equipment with higher levels of efficiency. Included in our capabilities is the design and building of tools and fixtures on-site, completely within our control. We include in our scope of operations assemblies, sub-assemblies, and families of parts. We can also arrange the procurement of raw materials and castings, and contract for outside finishing services such as heat-treat, plating, and painting.

Because of the rapidly changing environment in our industry, such as high-speed machining, vacuum work holding, tooling insert improvements, geometric tolerances, statistical process control requirements, and precision metrology, we conduct ongoing operator training both in-house and at training centers. We train the production crew in how to be constructively critical of their work quality, minimize waste of all kinds, and strive for constant improvements.

Back to Top

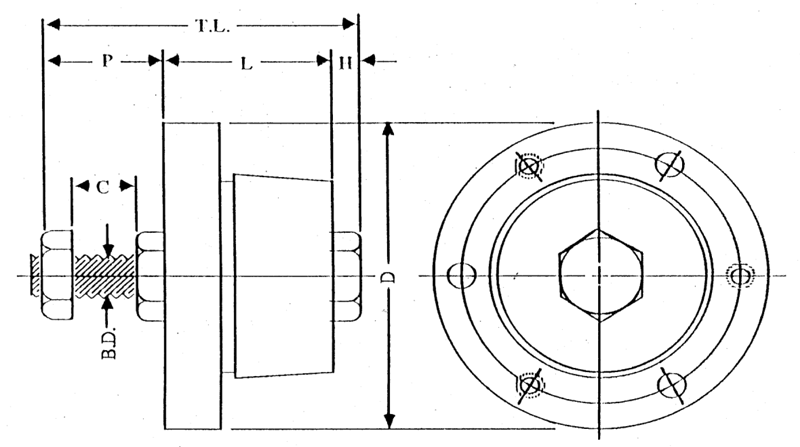

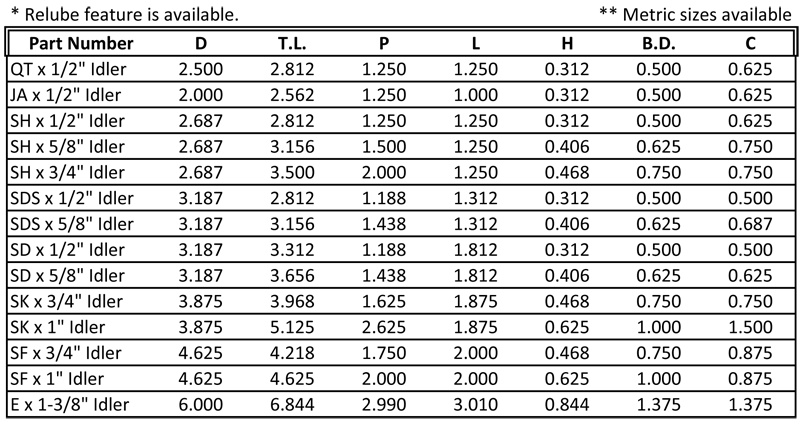

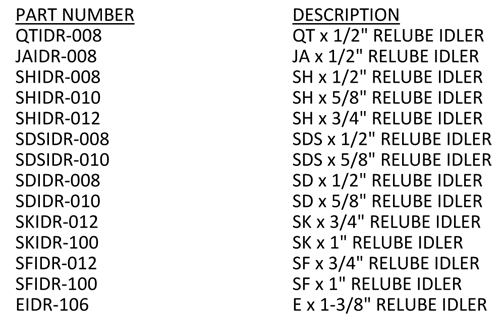

Relube Idler Bushings

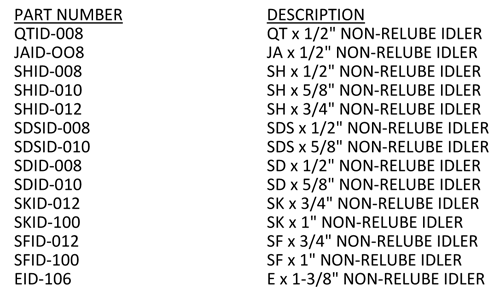

Non-Relube Idler Bushings

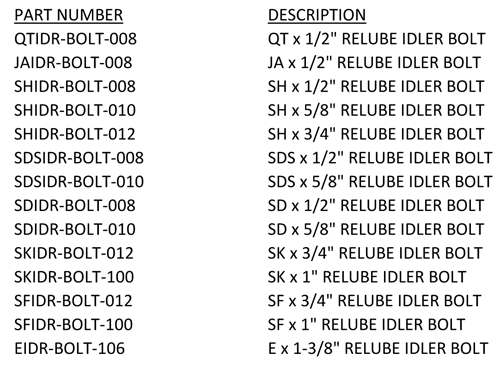

Relube Bolts

Back to Top

(2) 2001 Mitsubishi FX20 Wire EDM (Submersible)

- Max Workpiece Size: 41" x 31" x 11.5"

- Machining Range x-19.7", y-13.7", z-11.8"

- Max Taper Angle: 30 Deg

- Wire Diameter .004-.012"

- Class 12 Gear Capabilities

Back to Top

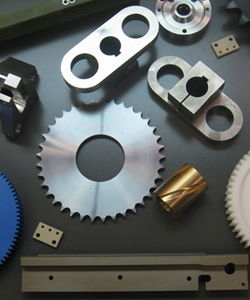

- CNC Turning & Hard Turning

- CNC Milling & Boring

- Welding

- Drilling & Tapping

- EDM Machining

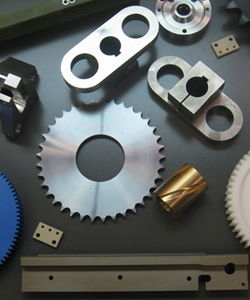

- Gear & Sprocket Manufacturing

- Spline Bores, Rebores, Keyways

- Burnouts (standard and complex shapes)

- Weldments (steel, aluminum and stainless)

- Machine Frames

- Blanchard and Roll Grinding

- Balancing of rigid and flexible rotors

- Grit Blasting and Painting

- Assembly of Machines and Sub-Assemblies

- Electrical work, Machine Wiring

- Design Work (CAD-AutoCAD Version 2006)

- Reverse Engineering Capabilites

- Kitting available of PT & OEM components

- To ensure ontime delivery, we offer warehousing of your products

Back to Top

- Parts to Customer Prints

- Specializes in Engineering

- EDM Machining

- Tolerances up to .0001"

- Gear Manufacturing

- Sprocket Manufacturing

- Timing Pulley Manufacturing

- Idler Bushing Manufacturing

- Spline Bores

- Rebores Keyways

- Drill and Tapping

- Hardened Ground Shafting

Back to Top

2000 Haas SL 30

- 14-1/2" Swing

- 34" Between Centers

Ikegai TU26

- 13-1/2" Swing

- 35-1/2" Between Centers

Webb Manual Lathe

- 14" Swing

- 80" Between Centers

Back to Top

2014 Haas VF4

- x-50, y-20, z-25

- 30HP, 8,100 RPM

2006 Haas VM1 Moldmaker (1)

- x-26, y-16, z-20 Travel

- 20HP, 12,000 RPM

2004 VF1 Mill

- x-20, y-16, z-20 Travel

- 20HP, 10,000 RPM

- Through Spindle Coolant

1996 VF3 Mill

- x-40, y-16, z-20 Travel

- 15HP, 7,500 RPM

Back to Top

2002 Hansford Davis Keyseater

- 3/16-1" Keyways

- 6 mm-25 mm Keyways

- Height to 8"

Back to Top

- Welding: TIG & MIG

(Alum, Stainless, MS) - Saws: Cut to 14" Dia - Autofeed

- Hydraulic Press - 100 Ton

- AutoCAD 2000LT

- Master Cam X3

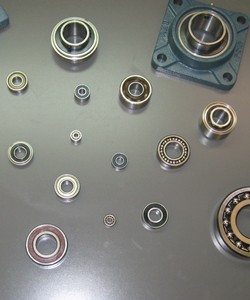

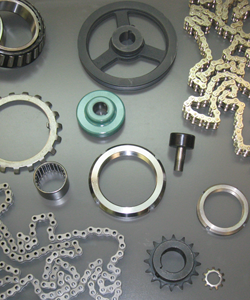

- Distribution:

- Bearings

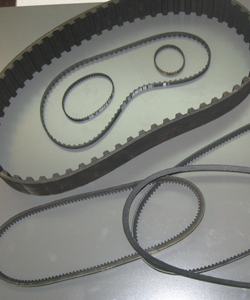

- Belts

- Gears

- Motors

- Reducers

- Couplings

- Sheaves

- Set Collars

- Roller Chain

- Drag Chain

- MTO Attachments

- Conveyor Pulleys

- Rollers

- Oil Seals

- Pulleys

Back to Top